Ribbon steel width material processing

Material:Ribbon steel

Plate thickness:0.3mm

Process:Press, clear painting

It is a product used for urinalysis in the processing example of medical related parts.

We purchase hardened ribbon steel that matches the product width of 2mm, and apply clear paint after processing.

Since the hardened ribbon steel is heat-treated already, so can be expected to reduce the process.

However, since it has already been heat-treated, it has a high hardness and is a difficult material to process.

Welding of leaf springs

Material:

【Body】SUS304 2B

(Austenitic stainless steel)

【Leaf spring】SUS304CSP-H

(Austenitic stainless steel)

Plate thickness:

【Body】1.2mm

【Leaf spring】0.8mm

Process:Press, welding、pickling process, Marking process on leaf springs

This is a leaf spring product used like a hose band. Stainless steel materials are partially welded together.

Welding characteristics vary depending on the type of stainless steel, so welding is not easy.

In addition, since burn marks remain on the product after welding, the burn marks are removed by performing a pickling treatment.

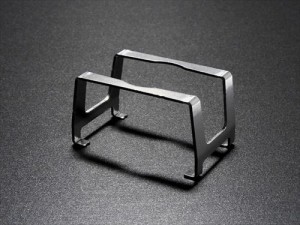

Lamp holder

Material:S55C(Carbon steel)

Plate thickness:0.5mm

Process:Press, Heat treatment,Parker processing, Powder coating

This is a product for fastening fluorescent lamps. This is also called a “lamp holder,” and is a typical leaf spring product for lighting.

With the spread of LED lighting, the fluorescent lamps are decreasing, and leaf spring products are mainly for LED lighting.

円錐バネ

Material:SUS301CSP

(Austenitic stainless steel)

Plate thickness:0.12mm

Process:Process by handThis is also called ‘bamboo shoot spring’ or ‘Taper rolled flat spring’.

A large load and absorbed energy can be obtained for the space occupied by the product.

When the applied area is narrow for the ordinary compression spring or requires more flexibility, this is very effective.

寸法切り順送加工

Material:SUS301CSP-3/4H

(Austenitic stainless steel)

Plate thickness:0.5mm

Process:Pressing

This is a project that is stamped to match the width of the product and material. If the width of the material is applicable to the product’s size, the cost can be cut by reducing the loss of the material

Hold spring

Material:Pure nichkel

Plate thickness:0.1mm

Process:Pressing、Aligned packaging

This is an example of processing using pure nickel, which has excellent corrosion resistance against harsh environments. We always try to take the best possible measures so that there are no problems when the product is used, by wearing gloves and not using press oil when processing the product.

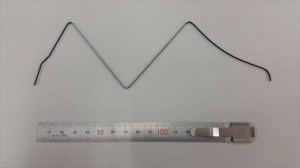

Single-shot bending

Material:SK85(Carbon tool steel)

Plate thickness:1.6mm

Process:Pressing (3 steps), barrel polishing, heat treatment, black dyeingWe are good at dealing with progressive press processing,

but we can also propose single-shot press for products with small lots and products

with shapes that are not suitable for progressive press processing.

This product is shaped over 3 steps.

In order to obtain pure roundness of the inner diameter, the product is bent into a wave shape by the first bending and

a beautiful ring shape by the second bending.

Processing of thin leaf springs

Material:SUS301CSP-EH(Austenitic stainless steel)

Plate thickness:0.13mm

Process:Pressing

We process thin stainless steel with a plate thickness of 0.13 mm using a progressive mold.

The burring part has a height of about 0.8 mm including the plate thickness,

and we have devised a molding method so that cracks do not occur during processing.

Small leaf spring

Material:SUS301CSP-3/4H(Austenitic stainless steel)

Plate thickness:0.3mm

Process:Pressing

It is a small leaf spring product with a height of 7 mm and a leaf width of 4 mm. It is a shape that is difficult to process due to cutting and bending of about 1.5 mm on both sides, but we process it with a progressive mold. We also pay attention to the matching.

Barrel finishing on stainless steel material

Material:SUS301CSP-3/4H(Austenitic stainless steel)

Plate thickness:0.8mm

Process:Pressing, Barrel polishing

This product has been barrel-polished to remove burrs after processing the product.

It is also possible to polish to make it shiny by barrel polishing to improve the appearance.

Even if the stainless steel material has a thickness of 0.8 mm,

some deformation may occur during barrel polishing and the dimensions could be unstable,

so we make full use of our know-how to ensure quality stability.