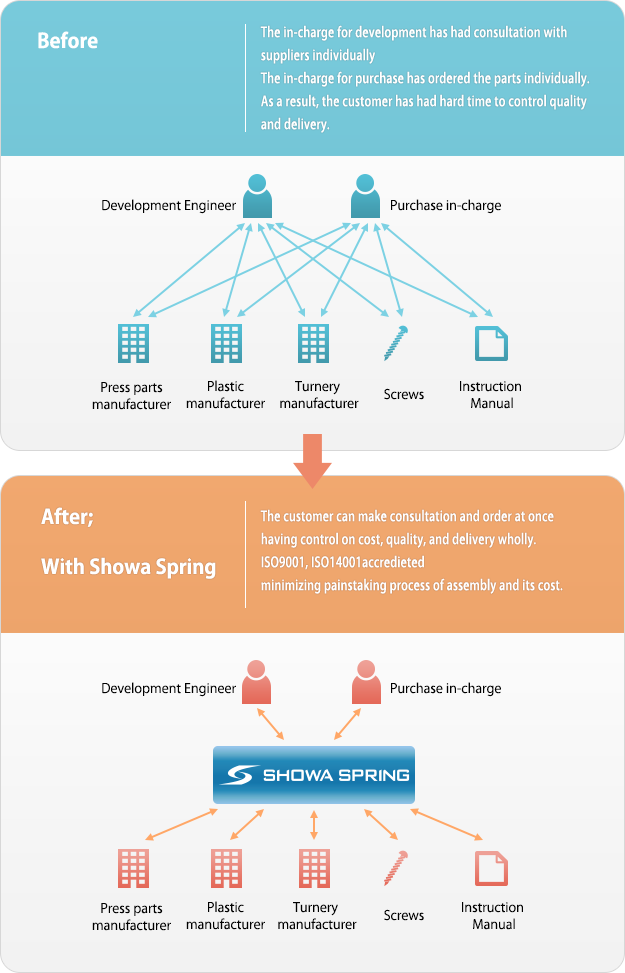

We save customers time and labor by manufacturing parts production and assembly together.

Shield Metal Fittings

Material:C5191P Plate thickness:t=0.1 Process:turret punch press processing, Sheet metal processing, degreasing

The material is soft phosphor bronze, and the plate thickness is quite thin at t0.1.

To prevent deformation, we form the round shape by processing several times to achieve an inner diameter of φ6.0.

Spiral fountain pen

Large coil spring

Material:SAE9254(Equivalent material to US standard silicon chrome steel SUP12) Size:Wire diameter Φ21×free length 200 Process:hot forming Surface Process:electrostatic powder coating

A hot-formed compression spring used in large plants.

The wire diameter is as large as φ21mm, and the maximum load is more than 30,000N.

Hot forming enables producing a thick spring or a large spring like this product.

Double torsion spring

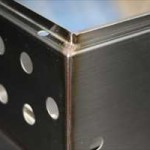

Philippine partner factory product④

Material:iron Plate thickness:2㎜ Process:laser, bender, tap surface treatment:Chrome-plated

This is an example of sheet metal processing at a partner manufacturer in the Philippines. After forming the outline with laser and bender, tap some of the holes and finish with chrome plating to improve rust resistance.

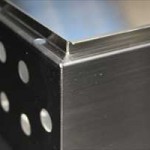

Philippine partner factory product③

Material:iron(Hot-dip galvanized steel sheet) Plate thickness:2㎜ Process:laser, bender, polishing、tig welding

This is an example of sheet metal processing at a partner manufacturer in the Philippines.

After processing the outline with laser, the plate is bent to form a box shape with bending machine.

After TIG welding, the outer shape is polished and the parts are bolted together. We are good at processing hot-dip galvanized steel sheets, so please contact us when you need it.

Philippine partner factory product②

Material:iron Plate thickness:3㎜ Process:laser, bender, polishing, tig welding

This is an example of sheet metal processing at a partner manufacturer in the Philippines.

For each member, the outer shape is punched by press processing, and bending is performed by bender processing., the surface is coated with white powder.

Complicated processing of large and thick materials can also be handled locally.

Philippine partner factory product

【 DATA 】

Material:iron Plate thickness:5㎜ Process:Laser, TIG Welding Surface treatment:Chrome-plated

In this product, the outer shape is cut by laser and the members are joined by TIG welding.

This is a processing example at a sheet metal processing partner manufacturer in Cebu, Philippines. From cutting to welding, integrated production is possible.

We can also handle powder coating and large and thick hot-dip galvanized products, so please contact us if you have any problems.

Fiber Laser Welding

Argon Welding

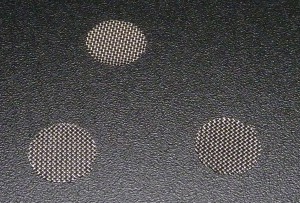

Wire mesh products

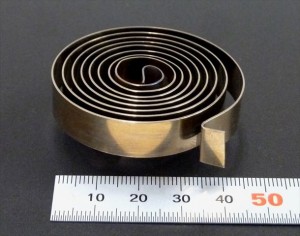

Flat spiral spring

【 DATA 】

Material : SUS301CSP-EH

(Austenitic stainless steel)

Plate thickness : 0.1mm

Process : Winding by machine and hand processing.

This is a small flat spiral spring. We can produce big flat spiral spring and S-shaped spring, too. Ribbon steel is also available. We perform assembly and support the state of the finished product.

This is used for sliding door closer, small wire fence, and other products.

Products using a flat spiral spring

We support the Flat spiral springs used inside the product.

Material:

SUS301CSP-EH

(Austenitic stainless steel)

Plate thickness: 0.15mm

Process: Winding by machine and hand processing

The product name is “Expand Belt,” a belt-type partition that can be used for various purposes.

It is sturdy, lightweight, and can be used with any object. The belt is wound up by the flat spiral spring inside.

Multi-forming process

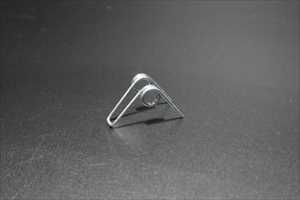

Proposal of wire spring

【 DATA 】

Material:SUS304WPB

Wire diameter:Φ1.5mm

Process:Machining process

It is a fastener that fixes pipes with different diameters, and is a product that processes stainless steel wire with a wire diameter of Φ1.5 instead of leaf springs.

Although it was possible to use leaf springs, we were able to manufacture wire springs without mold, so we designed and proposed the shape with wire springs.

At our company, we try to make the best proposal in consideration of the customer’s budget and product application.