Leaf springs for LED downlights

【 DATA 】

Material:HT1770(Precipitation hardening stainless steel)

Plate thickness:0.4mm

Process:Press, aging treatment (precipitation hardening treatment).

Leaf springs are also available for LED downlights.

Ceiling-mounted downlights needs extra care as it is done at high place, and with two hands.

(Holding the downlight with one hand and screwing it with the other.)

Therefore, we have developed a leaf spring that can be attached with one hand. That improved safety and workability.

It can be mounted on the ceiling with the leaf spring set on the downlight body.

This leaf spring was made possible by the HT1770 material, which has high spring characteristics.

Click the picture on the left to enlarge.

Curl bending of HT1770 material

【 DATA 】

Material:HT1770(Precipitation hardening stainless steel)

Plate thickness:0.3mm

Process:Laser processing, bender bending, aging treatment (vacuum precipitation hardening treatment).

This leaf spring product requires excellent springiness and the strength of SUS301CSP-EH.

The material hardness of SUS301CSP-EH is high, and it takes a considerable amount of time to bend the curl.

Since the HT1770 material has excellent molding and punching workability,

it is possible to handle curl bending in a short time.

Electrodeposition coating on SUS spring material

【 DATA 】

Material:SUS301CSP-3/4H(Austenitic stainless steel)

Plate thickness:0.3mm

Process:Pressing, Cationic electrodeposition coating.

Electrodeposition coating is a coating that forms a film by immersing a product in a

conductive water-soluble paint and passing an electric current through it. Even if the product has a complicated shape, it is uniform without leaving any residue, and because it is coated by a chemical reaction, it adheres firmly and the coating film has excellent corrosion resistance.

Quick fastener

【 DATA 】

Material:DP-2(High-strength double-phase structure stainless steel)

Plate thickness:0.8mm

Process:Pressing

DP-2 (double phase stainless steel) is used for the leaf spring that fixes the pipe for

cost reduction. Pipes with different outer diameters are fixed to each other,

and we will design and manufacture according to the outer diameter of the mating object.

Leaf spring for lighting

【 DATA 】

Material:HT1770(Precipitation hardening stainless steel)

Plate thickness:0.5mm

Process:Pressing, aging treatment (precipitation hardening treatment).

By using HT1770 material, we have realized a product with high strength and excellent spring characteristics, which was not possible with the conventional SUS301CSP material and SUS304CSP material.

Caulking high-strength SUS steel

【 DATA 】

Material:

【Body】SPG(Hot-dip galvanized steel sheet)

【Leaf spring】HT1770(Precipitation hardening stainless steel)

Plate thickness:

【Body】1.0mm

【Leaf spring】0.6mm

Process:Pressing, aging treatment (precipitation hardening treatment) of leaf spring, caulking

The leaf spring is caulked to the mating material of the hot-dip galvanized steel sheet. Only the parts that require high springiness are processed with NSS HT1770 (high-strength SUS steel made by Nippon Steel Stainless Steel).

Hexavalent chromate (galvanized) treatment

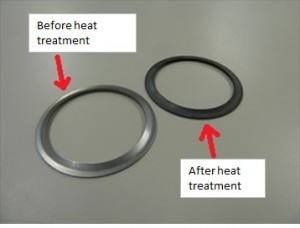

SK material hemming processing

SK material (special steel)

【 DATA 】

Material:SK85

Plate thickness:0.5mm

Process:

After removing the outer shape of the SK material and bending it by drawing,

austempering treatment is applied.

By heat treatment, the color will change as shown in the photo, but springiness will be created.

Rust prevention treatment such as plating is recommended for post-treatment.

NSS HT1770 processing example

【 DATA 】

Material:HT1770(Precipitation hardening stainless steel)

Plate thickness:0.12~1.0mm

Process:Pressing, aging treatment (precipitation hardening treatment).

A leaf spring that uses high-strength SUS steel called NSS HT1770,

which is a unique steel grade of Nippon Steel Stainless Steel.

Since this material has high springiness due to aging treatment,

it has both strength and moldability.

(When the hardness is low before the aging treatment,

the workability is good, and after the aging treatment, the hardness increases significantly.)

The product after aging treatment is also characterized by having a copper-like color.

Closet shaft bracket

Material:【Body・Washer】S55C(Carbon steel)

【Shaft】SS41B【Cap】resin

Plate thickness:【Body・Washer】0.8mm

Process:Pressing of body and washer, and heat treatment of washer

Surface treatment(trivalent chromate treatment, baking treatment)of body, washer and shaft,、assembly

This is a shaft for the aluminum closet.

To simplify the process, it can be attached to the door without screws. Also, in order to reduce the packing cost, the cap part can be stored short.

Click the figure on the left to enlarge.