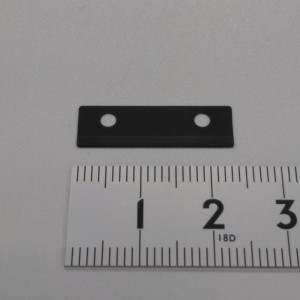

Low temperature black chrome plating on leaf springs

【DATA 】

Material:SUS304CSP-H

(Austenitic stainless steel)

Plate thickness:0.2mm

Process:Pressing, Low temperature black chrome plating on leaf springs

Low temperature black chrome plating is a special surface treatment that creates a black metal surface as seen in alloys. Due to the processing with excellent optical characteristics, this product is used for parts that require diffuse reflection prevention. Although it is a thin film, it also has excellent corrosion resistance.

Product processing with multi-phase stainless steel

【 DATA 】

Material:DP-2(multi-phase stainless steel)

Plate thickness:0.6mm

Process:Pressing, Barrel polishing

It is a product with a size of about 40 mm and is processed with a progressive press die.

We use NSS 431DP-2 (Nippon Steel Stainless Steel multi-phase stainless steel),

which has excellent workability and strength.

Compared to SUS301 material and SUS304 material,

the nickel content is low, so it has the advantage of being less susceptible to market fluctuations.

Aging treatment of leaf spring(HT1770)

【 DATA 】

Material:HT1770(Precipitation hardening stainless steel)

Plate thickness:1.0mm

Process:Pressing, aging treatment (precipitation hardening treatment)The HT1770 material always requires a heat treatment called aging treatment (precipitation hardening treatment)

in order to obtain appropriate springiness.

The surface before aging is the color of stainless steel, but after aging, it changes to a color close to copper.

The oxide film on the surface of the material discolors due to the reaction with oxygen in the atmosphere,

resulting in this color, but there is no problem in performance.

In addition, HT1770 material has good formability in cold working conditions,

and can handle processing that is difficult with ordinary stainless steel materials such as curl bending.

Leaf springs for small downlights

【 DATA 】

Material:HT1770(Precipitation hardening stainless steel)

Plate thickness:0.3mm

Process:Press, aging treatment (precipitation hardening treatment)The size is about 20 mm, which is small as a leaf spring for downlights,

but it requires higher springiness than ordinary SUS steel.

We proposed and processed NSS HT1770 (precipitation hardening stainless steel made by Nippon Steel Stainless Steel),

which has good formability and excellent spring characteristics.

Plating treatment on thin leaf springs

【 DATA 】

Material:SUS301CSP-1/2H(Austenitic stainless steel)

Plate thickness:0.2mm

Process:Pressing, Gold plating (rack processing)It is a terminal part of the battery used in wristwatches.

The thin gold-plated leaf spring with the thickness of 0.2 mm,

and each product is hung on a rack for processing (rack processing)

so that the product will not be deformed.

Utilizing our know-how, we have taken measures to prevent hanging marks as much as possible.

Lock spring

【 DATA 】

Material:S50C or S60C(Carbon steel)

Plate thickness:0.5mm~0.7mm

Process:Press, heat treatment, caulking, surface treatment (trivalent chromate treatment and baking treatment, disgo treatment)

Leaf springs are used as methods of connecting pipes such as scaffolding at construction sites, high branch cutting scissors, and snow shovels.

Pipes are connected and fixed by the engaging protrusions on the leaf spring side.

The processing methods are roughly divided into two types,

one is that the pin for the engagement protrusion is crimped,

and the other is that the protrusion is formed by drawing.

We can propose a variety of pipe diameter

design and processing method according to the cost,

application, and size.

Click the figure on the left to enlarge.

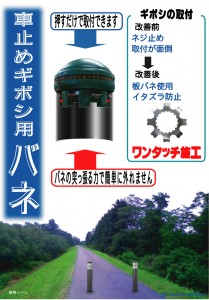

Leaf spring for bollard pole

【 DATA 】

Material:SUS301CSP-1/2H(Austenitic stainless steel)

Plate thickness:0.8mm

Process:Pressing

Some parks have a resin cap attached to the tip of the bollard pole.

Conventionally, the resin cap and pole were screwed together,

but by using a leaf spring, it can be installed with one touch,

reducing the workload and preventing theft damage.

The leaf spring that spreads in eight directions is hooked

so that the top part (giboshi) will not come off from the pole.

Click the figure on the left to enlarge.

Processing with progressive type (matching)

【 DATA 】

Material:SUS304CSP-1/2H(Austenitic stainless steel)

Plate thickness:0.3mm

Process:PressingWhen stamping with a progressive mold, burrs are likely to occur in the parts that are punched in several steps.

In order to prevent it, we process it by providing a joint called “matching”.

A dent will occur in the part where matching is provided.

In the product in the photo, matching occurs at the four tips and the center of the product.

Stainless steel taper processing

【 DATA 】

Material:SUS304CSP-3/4H(Austenitic stainless steel)

Plate thickness:0.5mm

Process:Pressing、taper processing and barrel polishingThe end face of the product is shaved diagonally (tapered) to give it a slope.

If it is not possible to make a gradient by Tsubushi (pressing), we perform taper processing with a cutting machine.

Nut spring

【 DATA 】

Material:SUS304CSP-H(Austenitic stainless steel)

Plate thickness:0.5mm

Processing: Pressing, surface treatment (disgo treatment), assembly (assembly work of leaf spring and nut)

This leaf spring is intended for outdoor use. Therefore, disco processing is applied after press processing.

Disgo treatment is a chrome-free, highly corrosion-resistant surface treatment that meets environmental needs.

Stainless steel is also prone to rust in harsh outdoor environments. Even in such an environment, corrosion resistance can be improved by applying more surface treatment.

We support consistent manufacturing from surface treatment to assembly as well as press processing.

By all means, we will proactively propose ideas for problems related to everyday manufacturing.