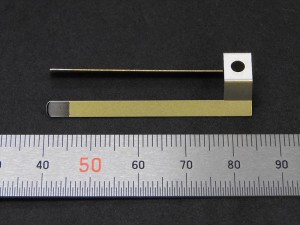

Slide Scale Clip

【 DATA 】

Material:SK85

(Carbon tool steels)

Plate thickness:0.4mm

Process:Pressing, heat-treated,

buffing process, Painting

This is one of our original products,

“Patti series”. A fall prevention clip

for scales (150mm ruler).

Since it is a slide type, you can freely

adjust the clip position.

It can be clipped to any depth of

the pocket, and it can also prevent

holes from being punctured in the pocket

with straightedge corners.

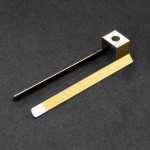

Plating treatment for tiny parts

【 DATA 】

Material : C1100P (tough pitch copper)

Plate thickness : 0.3mm

Process : Pressing, gold plating

(including sealing process)

It is a very small product with a

size of about 10 mm. We use tough

pitch copper with excellent

workability and corrosion resistance.

In order to match the cost, it is

necessary to perform plating by

barrel processing, and we utilize

our know-how to prevent deformation.

Insulation treatment for phosphor bronze

Material:C5210-H (phosphor bronze for spring)

Plate thickness : 0.2mm

Process : Laser, general-purpose bending,

nickel plating, insulation treatment

It is a product in which phosphor bronze

is nickel-plated and then an insulating

coating is applied on top of it.

The light-ocher part of the product

is insulated and has passed the

voltage test 100V (measured by clipping the coating).

Connector parts

Material :C5210-H

(phosphor bronze for spring)

Plate thickness : 0.25mm

Process : Pressing, crimping, electrolytic

nickel plating, rack processing

It is crimped to fix the shape of the

product, but if too much force is applied,

the shape will easily collapse.

Since this is a product which requires

strict quality standards, it is a difficult

process to adjust the needs. Since the

product is thin and crimped, plating is

performed by rack processing.

Unlike barrel processing, each product

is processed with a jig, so deformation

and color unevenness are unlikely to occur.

Pocket notebook clip

Material :

SUS304CSP-3/4H (Austenitic stainless steel)

Plate thickness : 0.8mm

Process : Pressing, barrel polishing

This is a clip which can be used

with a notebook. Ball point pens

can be attached on it. The photo

shows a product which had the

deburring treatment, but the

appearance can be changed by performing

additional surface treatment.

Click the picture to enlarge

Cord clip

Sun levee clip

Material : HT1770

(Precipitation hardening stainless steel)

Plate thickness : 0.6mm

Process : Pressing, aging process,

precipitation hardening process

This is a clip to attach sun levee

to a cap. Since the HT1770 material

has good workability and excellent

springiness, it can exhibit springiness

even in the small product. By combining

with resin parts, it can be attached

to the shade with a better clip feeling,

and it is hard to come off.

Sponge catcher

Material :SUS304CSP-1/2H

(Austenitic stainless steel)

Plate thickness : 0.35mm

Process : Pressing, surface

treatment (Painting)

This is a product that drains

water by hooking a sponge on

the nail part. Since we use

paint that does not crack easily

even when the product is bent,

it can be bent freely.

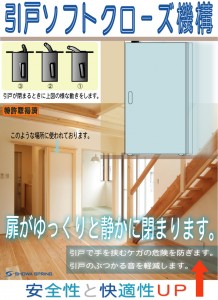

Sliding door soft closing mechanism

Material :

SGCC(White painted steel plate)

【Body cover】,

HT1770

(Precipitation hardening stainless steel)

【flat spring】

Plate thickness : 1.0mm【Body cover】,0.6【flat spring】,

Process : Pressing, aging process

(precipitation hardening process), assembling

You can close the sliding door softly by this mechanism even when you slam the door.

This prevents the doors from causing sound upon closing and your fingers from jamming in them.

We develop together with our customers from the start-up, and we handle everything from in-house pressing, purchasing of parts and assembly. We will actively cooperate with development of our customers’ new products.

Click the left image to enlarge.

Wiper blade

Wave Washer

Quick fastener(Exhibition display items)

Material:DP-2(Multi-phase stainless steel)

Plate thickness:0.8mm

Process:Press

This is a leaf spring for attaching the pipes with one touch.

The main merit is that the workability is much better than using bolts.

The photo was taken at the 19th Kansai Machine Element Technology Exhibition (M-Trch Kansai) when it was exhibited together with an in-house produced object.