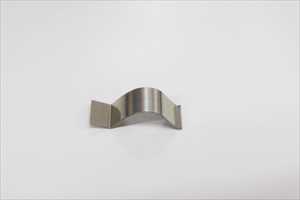

配線用板バネ

Material:SUS304-H

(Austenitic stainless steel) Plate thickness:t=0.2 Process:Progressive pressing process, Degreasing, bagging

This is a leaf spring produced by progressive press processing.

After degreasing, we are doing bag packing.

In addition to the press, we are able to packaging products in the assembly process.

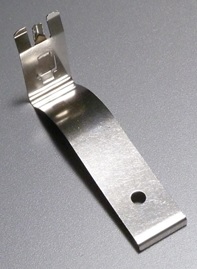

ガイド金具

Material:SUS304-2B Plate thickness:t=1.5 Process:

Progressive pressing process, barrel polishing

This is a processing example of progressive press and barrel polishing for stainless steel material. This products are symmetrical to each other, enabling one mold to produce both left and right parts. This also saves cost. We have a variety of processing methods for customers’ desired shape.

Tarp pole

Blade spring for carabiner hook

Material:HT-1770 Plate thickness:t=0.6 Process:Pressing, Washing & heat treatment

This blade spring is made of precipitation hardening stainless steel hardened by heat. After progressive pressing and washed, it has heat hardening (aging). It may be hard to process forming shape with SUS631, we have various choices including HT1770

Heater clip

Copling

Manufacturable specification range Material:SUS301(Spring part) Plate thickness:0.1㎜~0.7㎜ Width:5㎜~100㎜

Load (torque): 15g to 35kg (per piece)

This “copling” that operates with constant load and constant torque, regardless of the amount of elongation or deflection.

《Usage》 ①Lifting device:Supports lifting and lowering heavy objects with little force.

②Balancer: Balances (stops) an object at decided position

③Motor:Adopts a winding method on a drum Please contact us for more information.

-Patti PIPE JOINT CLIP - Multicolor

Material:

SUS304CSP-H

(Austenitic stainless steel)【Body】

SUS303(Austenitic stainless steel)【Pin】

Process:

Pressing 【Body】

cutting【Pin】

Powder coating【Body and Pin】

New colors were added to the joint clip of our original product “Patti series”.

This is an example of powder coating applied to the main body of stainless steel.

One-touch mounting leaf spring

Austempering

【 DATA 】

Material:SK-85(Carbon tool steel)

Plate thickness : 0.8mm

Process:Pressing and heat treatment

This is an example of heat treatment

(Austemper treatment)

after one-shot press processing.

By performing heat treatment, the color

will change as shown in the photo,

but springiness will be created.

Rust prevention treatment such as

plating is recommended for post-treatment.

Leaf spring for lighting

Hemming processing

【 DATA 】

Material:SUS304CSP-3/4H

(Austenitic stainless steel)

Plate thickness:0.4mm

Process:Press, barrel polishing

This is an example of a product

that has undergone hemming bending.

The center of the product is bent

in two places. It is an effective

processing method for ensuring product

strength and safety measures.

Tip bending process

【 DATA 】

Material:SK85(Carbon tool steel)

Plate thickness:1.5mm

Process:Press、heat treatment, surface treatment

(trivalent chromate treatment and baking treatment)

This is a product with size of about 23 mm.

This product has convex parts of about 2 mm,

and the convex parts are bent and molded into

twisting shapes. The process is performed at once.

Hold spring

【 DATA 】

Material:HT1770(Precipitation hardening stainless steel)

Plate thickness:0.6mm

Process:Press, aging process(Precipitation hardening)

It is a leaf spring product with

a plate thickness of 0.6 mm and

the length of about 50 mm.

We perform aging treatment (precipitation

hardening treatment) in-house.

Due to the influence of the oxide film

by aging treatment, the surface of the

product turns brown.

If the discolored surface is a problem,

vacuum heat treatment can be applicable

to prevent the color tone.

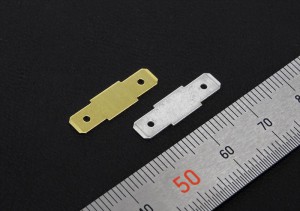

Processing of brass material, plating

Click flat spring

Seamless slide bracket

【 DATA 】

Material : SUS301CSP-3/4H

(Austenitic stainless steel)

Plate thickness : 0.3mm

Process : Pressing

A leaf spring for lighting equipment.

It is used when installing the LED

light by sliding it, and it can be

easily attached and detached.

We also produce leaf springs for

many lighting fixtures, such as leaf

springs for downlights.