Progressive pressing process

Single-shot bending

Burling processing

Counterbore press processing

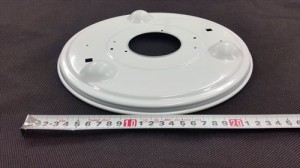

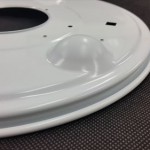

Drawing and hemming process

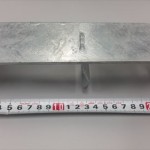

【 DATA 】

Material : SGCC

(Hot-dip galvanized steel sheet)

Plate thickness : 1.2mm

Process : Pressing【Mass-produced product】

This is an example of a product which had processed drawing and hemming.

The hemming process on the plated steel sheet is a process in which dents are likely to occur because a large amount of peeled material powder is generated, but the occurrence of the dents is suppressed by devising a coating on the mold.

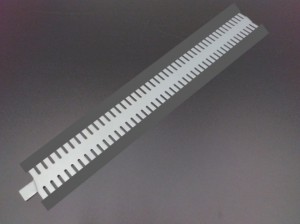

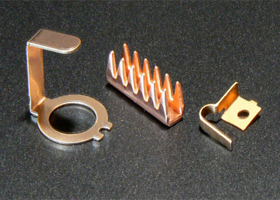

Pressing spring

【 DATA 】

Material :Pure nickel material

Plate thickness : 0.1mm

Process : Pressing, aligned packaging.【Mass-produced product】

This is an example of processing using pure nickel, which has excellent corrosion resistance against harsh environments.

When taking care of this product, wearing gloves and not using press oil is needed. We always try to take the best possible measures so that there are no problems depending on the material.

Aperture bending

【 DATA 】

Material:SUS304 2B

(Austenitic stainless steel)

Plate thickness :1.0mm

Process : Pressing, barrel polishing【Mass-produced product】

The side of this product is drawn and bent. Drawing bending is a difficult process because the material is easily stick to the mold, but we have devised a special coating on the mold to prevent sticking together.

Product processing with highly corrosion-resistant galvanized steel sheet

【 DATA 】

Material:ZAM(High corrosion resistant hot-dip galvanized steel sheet)

Plate thickness :1.6mm

Process : Pressing【Mass-produced product】

The product size is 30mm and is press-processed using ZAM

(Nippon Steel’s highly corrosion-resistant galvanized steel sheet).

This material has better workability than general hot-dip galvanized steel sheets and has good elongation to the end face,

so it is also suitable for thick products.

In addition, the protective film melted from the plating layer covers the

processed cross section, so it has excellent corrosion resistance.

Since no surface treatment is required for post-processing,

total cost reduction can be expected.

Measures against burrs on stamped products

【 DATA 】

Material:SUS304 2B

(Austenitic stainless steel)

Plate thickness:1.0mm

Pressing, barrel polishing【Mass-produced product】

Pressed 2B, which is temper-rolling material, and then had

barrel-polishing to remove burrs.

Since there is a risk of deformation in normal barrel polishing,

we have devised ways to prevent

deformation by adjusting the amount of media (abrasive stone / abrasive) and process time.

Stainless curl bending

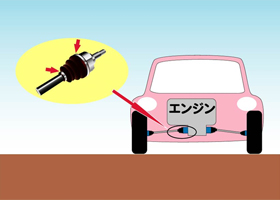

Band parts for automobiles

【 DATA 】

Material:SUS304 2B

(Austenitic stainless steel)

Plate thickness:0.8mm

Process : Pressing

【Mass-produced product】

A leaf spring for fastening rubber boots and preventing grease leakage.

Automobiles have a mechanism called a constant velocity joint that transmits the driving force from the engine to the tires,

which are covered with rubber boots. This is an important part that corresponds to the mechanism of the drive system.

Originally, the band was fastened with screws, but we proposed a screwless, one-touch type and our customer adopted it.

In addition to OEM, we actively support ODM according to our customer’s request.

CGCC(White painted steel plate)

Welding and galvanizing

Architectural hardware

We supply press processed metal parts for strike front of entrance door, closet door, lock parts, and so forth. And we are capable to assemble them.

Strike front’ is processed in multiple ways such as bending and drawing, which has been having a problem with breaking blue protective sticker, however, we’ve improved the process by adjusting contact pressure on the molds and now it has less problem.

Tools

Wire springs

Terminals

Hinges

Flat springs

Metal components for construction

Pipe connection fittings for construction materials.

Metal joints for construction materials.

Those materials have high corrosion resistance with disgo treatment on special steel.

Transfer press processed item made of 3/4H (stainless steel spring material).

The process of curling part is remarkable. They are used as stopper

for the hood of extractor fan.

Material: SUS301 3/4H

【Mass production】